What is Teflon?

Teflon, chemically defined as polytetrafluoroethylene (PTFE), is a synthetic polymer of tetrafluoroethylene made entirely of carbon and fluorine; characterized by a high molecular weight, it shows a completely solid consistency.

Teflon has strong hydrophobic capacities, thanks to the high electronegativity of fluorine; moreover, it boasts one of the lowest coefficients of friction currently known (which is why it is used in the kitchen as a non-stick coating for pots, pans, dripping pans, utensils, etc.).

Being not very reactive, in part thanks to the strength of the bonds between carbon and fluorine, it is often used for the production of containers and pipes for highly reactive and corrosive chemical liquids.

If used as a lubricant, Teflon reduces friction, hence the wear and energy consumption of the machines.

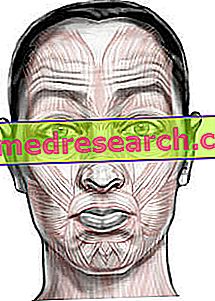

Last but not least, Teflon is also used as a grafting material in surgical procedures.

Risks of pyrolysis

Teflon is best known for its use as a non-stick coating on pans and in other kitchen utensils, as it is hydrophobic and highly resistant to heat.

However, leaving a Teflon-coated pan to be subjected to the flame of a stove, the compound undergoes a degradation proportional to the specific time and temperature.

In fact, the pyrolysis (thermochemical decomposition) of Teflon is detectable at 200 ° C (392 ° F) for the generation of various fluoro-carbon based gases and sublimates. Nevertheless, an old animal study (from 1955) concluded: "it is unlikely that, at temperatures below 250 ° C (482 ° F), these products could be generated in significant quantities that could harm the health of the animal organism ".

This means that, despite being stable and non-toxic at lower temperatures, Teflon instead begins to deteriorate significantly when these reach around 260 ° C (500 ° F) and probably decomposes strongly above 350 ° C (662 ° F) . These byproducts of teflon pyrolysis have been shown to be lethal to birds and cause flu-like symptoms in humans.

Meat is generally cooked between 204 and 232 ° C (399 and 450 ° F) and most fats start smoking before the temperature reaches 260 ° C (500 ° F). However, we recall that there are at least two edible oils that boast a superior smoke point, namely refined safflower oil and avocado oil (the palm oil, one of the most widely used in the world, has a smoke point of around of 245 ° C).

Risks of Teflon Ingestion

The risk of ingestion of Teflon with food is different but likely.

This material can be hidden in the food if scraped from the surfaces that contain it by means of metal tools (spatulas, forks, spoons, ladles, etc.); in fact, to prevent this from happening, it is advisable to use tools made of more specially designed softer materials.

Although it is still sufficient to avoid vigorously rubbing the Teflon non-stick cooking utensils in order not to ingest some fragments, it is nevertheless necessary to specify that the very small parts possibly taken with the food do not undergo any digestion and / or absorption; in a nutshell, they pass the digestive tract and are totally expelled with faeces.

Perfluorooctanoic acid

Perfluorooctanoic acid (PFOA) is a chemical element sometimes used in the production of Teflon; this would be used as a surfactant in the polymerization of certain emulsions (mixtures) of Teflon. Currently, many producers have completely stopped its use, as it tends to persist indefinitely in the environment and is toxic-carcinogenic to animals.

PFOA has been detected in the blood of over 98% of the general population of the United States and its levels are higher in chemical plant workers, as well as in the surrounding population.

Americans' exposure to perfluorooctanoic acid is mainly due to the discharge of waste into the ocean and near the Ohio River valley over the past fifty years.

PFOA is detectable in industrial waste, stain-resistant carpets, carpet cleaning liquids, anti-dust products, microwave popcorn bags, water and food themselves and some non-stick cookware which, of course, contain teflon enriched with perfluorooctanoic acid.

As a result of a class-action (mass legal action) against "DuPont", three epidemiologists conducted studies on the population surrounding a chemical plant that was exposed to higher levels of PFOA than the general population. The investigations concluded that, probably, there is a direct association between exposure to PFOA and six types of health impairment, such as: kidney cancer, testicular cancer, ulcerative colitis, thyroid disease, hypercholesterolemia and gravidic hypertension.

On the other hand, by examining with greater specificity the health implication linked to the use of non-stick teflon pans, this is considered to be completely insignificant.

Property

Teflon is a thermoplastic polymer, with a solid and white color (at room temperature); its density is about 2200 kg / m3. According to the "DuPont", the melting point is 327 ° C (620 ° F); at -268.15 ° C (-450.67 ° F) it maintains high strength, toughness and self-lubrication, while at temperatures above -79 ° C (-110 ° F) it also has good elasticity.

The coefficient of friction of teflon (measured on liquid steel) is between 0.05 and 0.10, which is the lowest third of any known solid material (after the Aluminum Magnesium Boride and the Diamond Like Carbon ). Teflon cannot be crosslinked like an elastomer, it has no "memory" and is often used as a gasket material.

Other Applications

The main application of Teflon (50% of production) is in the wiring of aerospace and IT applications, for example the connection of wires, coaxial cables etc.

In industrial applications it is used where a sliding action is required, such as joints, gears, sliding plates etc.

Teflon film is also widely used in the production of carbon fiber and glass fiber composites, on which it is interposed to prevent the materials from sticking.